Close

Veritas Engineers & Erectors — 15+ Years in Precision PEB Manufacturing & Erection.

With specialized experience in Pre-Engineered Buildings, Veritas delivers engineered steel structures for data centers, warehouses, industrial facilities, logistics hubs, and infrastructure projects. Our offering combines advanced structural design (finite-element analysis, load-path optimization), in-house fabrication with CNC automation, strict material traceability, and site erection governed by engineered erection sequences and safety protocols. We integrate shop-level NC control, non-destructive testing, and a quality management regime to ensure dimensional accuracy, durability, and predictable programme delivery for even the most demanding industrial clients.

The PEB process begins with the Request for Quotation (RFQ), where the client shares detailed project requirements such as building dimensions, load conditions, functional needs, and site-specific data. Based on this input, our technical team carefully studies the specifications and prepares a precise cost estimation covering steel structures, roofing, cladding, and accessories.

Here, we use advanced estimation methods integrated with the latest material rates, engineering codes, and structural standards to ensure transparency and accuracy in pricing.

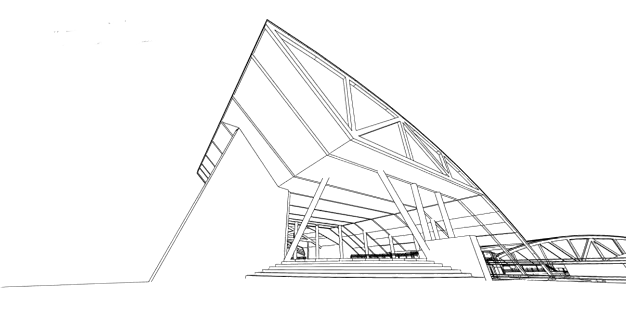

Our process begins with a thorough understanding of the client’s exact requirements. At Veritas, we provide complete designing, detailing, and engineering solutions—including GA drawings, shop drawings, and all necessary documentation.

Every design is tailored to the client’s specifications, ensuring precision, functionality, and seamless execution at the site. Our in-house design and engineering team ensures that every structure we deliver is practical, efficient, and built to last.

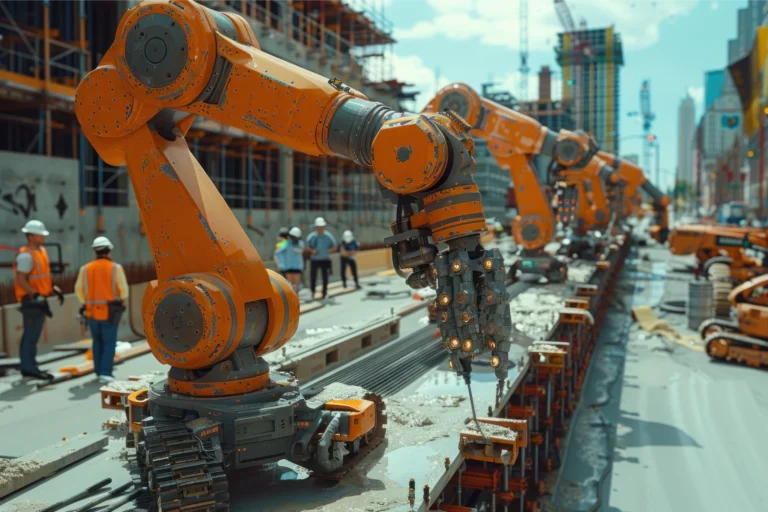

Operates through two dedicated production units having capacity of 1500MT per month equipped with advanced, high-tech, and fully automated machinery. Each unit is specialized to manufacture key components and other structural elements with the highest precision.

We utilize specialized machinery for different processes, ensuring efficiency, consistency, and superior quality at every stage of manufacturing. Our automated systems minimize errors, reduce timelines, and deliver world-class PEB solutions tailored to client requirements.

We leverage advanced, fully automated machinery to deliver precision-engineered products. Our modern infrastructure ensures accuracy, efficiency, consistency, and superior quality across every project. All in-house machinery and testing equipment are third party calibrated and recorded by our skilled maintenance team.